Welcome to the Community View section of the website. This area is dedicated to articles of interest, community information and local topics that are submitted by members of the public or guest writers. It is also the main section dedicated to the Youth Media Group Project.

9/5/2019 by

2

Adapted from the Northumberland County History: Earsdon and Horton.

The district surrounding Blyth possesses coal measures overlaid by boulder clay, and is a repetition of the northern portion of Tynemouthshire, to the south of this region.

Its surface is level and wind-swept, but, scenically uninteresting as it is, it forms a land well adapted for mining operations and the construction of the railways necessary for that industry. Underground, the coal seams, dipping seawards from their outcrops in the western portion of the district, are found on its eastern edge at comparatively moderate depths and are free from any serious faults or mining difficulties. Practically the whole of the seams of the North of England coalfield are met with.

Passing northwards from the Tyne, the character of the seams changes greatly, the house and gas coals of the Tyne area being replaced by the well known steam coal which forms the staple trade of the Blyth district.

To this difference in the nature of the coals the long interval separating the development of the Tyne and Blyth coalfields was due, domestic requirements affording the Tyne a widespread market many years before the introduction of steam power gave the northern district its long delayed opportunity for expansion.

The earliest record of mines in Cowpen is contained in the Tynemouth Chartulary, according to which the mines of Cowpen were held from the priory of Tynemouth by Robert, son of Alan of Cowpen, in the year 1315. [A great deal of the land at Cowpen had been granted to the various local religious organisations.] Salt pans in Cowpen were granted at the close of the twelfth century to the monks of Brinkburn. Tynemouth priory had salt pans in the same place in 1323; and coal was, no doubt, worked in conjunction with them from upper seams lying at shallow depths near the river Blyth, on the north side of which, namely, in Bedlingtonshire, the abbey of Newminster also possessed salt pans and coal mines which they leased up to the time of the dissolution.

In 1535, the prior and convent of Tynemouth leased to Nicholas Mitford and John Preston [small landholders at Cowpen] one coal pit with 2 picks [2 labourers] to be wrought at the said pit in the fields of Bebside and Cowpen for seven years, and in 1538 to Richard Benson of Durham two salt pans, with the garners and housing thereto appertaining, situate on the river of Blyth in the lordship of Cowpen for forty-one years, together with half a coal pit in the fields of Cowpen and Bebside, so long as the mine lasted, for the use of two salt pans, with wayleave and stayleave over the fields of Cowpen and Bebside.

After the dissolution of the monastery in 1539, the salt pans and coal pits were leased by the Crown to various individuals. In 1554 Thomas Bates took a lease of two salt pans and two coal pits which was renewed in 1574. Another lease was granted in 1555 to John Preston of one coal mine with two picks which was renewed in 1573 to Thomas Preston, his son. The lease included a covenant to serve the queen with horse and armour when required.

About this time the Percy family held property in Cowpen, formerly in possession of the Harbottles, and, in 1551, Dame Eleanor Percy leased three salt pans on the south side of the river at Cambois-ford, with coal mines for them, to Thomas Harbottle of Horton. These were subsequently leased by the Crown in 1576, after the attainder of the seventh earl of Northumberland, to Ralph Harbottle with wayleave and wood from the queen's woods for timbering the pits.

The produce of the mines seems at this period to have been almost wholly consumed in the manufacture of salt, for which the river gave an outlet to the various markets down the east coast, at Yarmouth, where it was used for herring curing, and in the Humber and elsewhere. Hartley was also a large salt-producing village at the time, shipping part of its output at Blyth. The works at Hartley were the property of Sir Robert Delaval, who, in 1576, extended his operations and became the tenant of the pans and mines at Blyth [in the vicinity of today's Commissioners Quay] formerly the property of Newminster abbey. These had been leased by the Crown after the dissolution to Richard Tyrrel of London in 1546, passing from his hands into those of Sir Thomas Grey in 1547 before they were assigned to Delaval.

[Saltworks are mentioned as early as 1201 and are located along the river for a distance opposite the mouth of the Sleekburn and Hodgson Road estate. Salt pans were used to boil and evaporate sea water leaving a deposit of salt. They were like a giant wok made of iron, although the earliest ones may have been made from lead. A structure was in place to hold the pan and contain the coal fire underneath and a shed to offer shelter. A building called a garner was used to store the salt prior to shipping. In 1736 a further six pans were constructed at Blyth by the Ridley family, having purchased them from the recently defunct Cullercoats works. Six cottages were constructed for workers so presumably a small labour force was involved in salt making. Wallace in "The History of Blyth" talking of salt manufacture in the 18th century writes "The labour in making salt was chiefly done by females. They pumped the water, wheeled the coals in barrows and shovelled the coals in firing the pans. Their wages were very small which the eked out by teasing oakem and pilfering small quantities of salt on which the duty that was levied made it of considerable value. In 1807 salt was selling for £34.10s, £30 of which was duty. Saltworks were leased for a great deal more than a coal pit in the 16th century and previous to this time."]

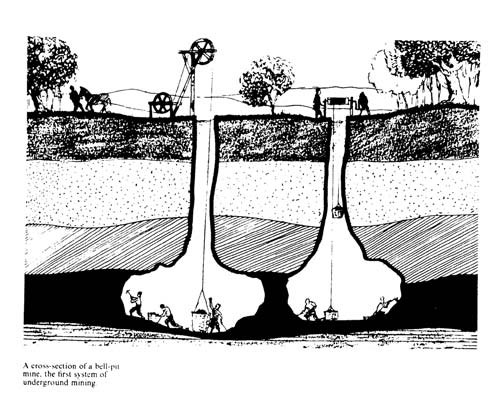

The general system of leasing by the Crown appears to have consisted roughly in the allotment to each lessee of two salt pans with a coal pit, the coal lease being one of so many picks or men's work without any boundaries being set out. The lessees had the right to sink pits where they chose, with liberty of wayleave and stayleave, the area worked by each pit being regulated by an old custom agreed upon by the farmers of the queen's coal mines, to the effect that every farmer's pitmark should be distant from one another twenty fathom sideways on each side of the pit to be sunk. These limits would include nearly one-and-a-half acres as the ground to be worked by each pit, though whether they were adhered to seems to be questionable, judging from an old plan of very little later date, from which it would appear that the shafts were irregularly placed and at smaller distances apart than those above mentioned.'

Towards the end of the sixteenth century the working of the Crown mines seems to have been almost altogether discontinued and the lessees ceased to pay rent, by reason, as it was alleged, of the 'decay of the coal mines.'

In 1595, however, a new departure was made, and in that year the Crown leased to Peter Delaval, a London merchant, already embarked in the coal trade at Preston, and Ambrose Dudley, the whole of its coal mines in the fields of Cowpen and Bebside, with nine salt pans. Opposition was made to Delaval and his partners, John Heighlord and Robert Waldo of London (the assigns of Dudley), by John Preston, a freeholder and owner of three salt pans in Cowpen, who asserted that he was the holder of a lease of two picks under the Crown, but failed to substantiate his claim in an action which he brought in 1596.

Delaval and his partners commenced to develop their property vigorously. They expended capital in sinking fresh pits and in erecting new salt pans and repairing the old ones. The pits at this period were

situated on land known as Cowpen East Field, then used as common land [each farmer being allotted strips in an open field on a periodic basis] and lately laid down from tillage under the system at that time in vogue. It may reasonably be assumed that the ground in question lay to the east of the present village of Cowpen adjoining the river, on the neighbouring banks of which it appears that four of the salt pans were placed, the remainder being probably nearer the sea.

The seam worked must have been that known locally as the Moorland seam, which lies at a depth of about eight fathoms (48 feet) below the surface near Cowpen village, the cover increasing to about twenty fathoms in the vicinity of the Cowpen North pit. This is confirmed by the statement made in the record of the survey of the king's mines in 1621, to the effect that the pits formerly worked were eight or nine fathoms deep, the seam about seven quarters of bad quality being an open salt-pan coal. This seam produced a coarse class of coal, fitted only for salt making, and unsuited for the coasting trade in coal which was then chiefly situated on the Tyne. In 1609 the shipments of coal from Blyth amounted to only 855 tons, and it is evident that the trade of the port was then entirely dependent on the manufacture of salt, to which coal mining was subsidiary. [Tynemouth Priory was mining coal by the 14th century on their land of Tynemouth, Preston, Chirton, Monkseaton and Earsdon where the Bensham seam outcrops. This was chiefly for landsale and salt pans which were established at Cullercoats, Hartley and Tynemouth. It was reported that a pit could be sunk to a depth of five fathoms (30 feet) in twelve days at a cost of £2.00.]

The Crown lessees encountered further opposition in their undertaking in 1599, owing to an attempt made by certain freeholders to work the coal underlying the strips, or riggs, of ground which had been held by them when the land had been in tillage. An action was consequently brought by Delaval and his partners against John Preston, Richard Preston and Cuthbert Watson, who had commenced working coal under 'riggs,' formerly occupied by themselves and other freeholders, carrying away the

produce of their pits over the Crown lands to salt pans owned by John Preston, and working the coal, as it was alleged, unskillfully and in such a way as to cause danger of water entering the mines of the queen's farmers (miners) and of the roof falling and destroying the mines. The freeholders alleged that the Crown had no right to work under their riggs except by composition with them. There is, however, no record to be found of the result of the controversy, though it seems probable that, with the exception of the Widdringtons, who had allowed the coal under their riggs to be worked by the Prestons, and whose rights were based on an alleged composition with the monastery of Tynemouth (subsequently safeguarded in the division of the lands of Cowpen in 1619), the freeholders failed to make good their claim.

Delaval was unfortunate in his ventures and failed before 1602. His partners did not continue to carry on the concern and assigned the lease to Thomas Harbottle of Horton-Stickley, who in turn appears to have handed it on to a company of capitalists from the Midlands, consisting of Sir John Ashburnham of Nottingham, Huntington Beaumont of Bilborough, near the same town, his brother-in-law Sir Henry Barkeley of Wymondham, Matthew Saunders of Shankton in Leicestershire, and Richard Paramore.

The Midland lessees seem to have been as unsuccessful as the Londoners, and were soon forced to rearrange affairs and to fall back again on London for further supplies. These were afforded by Edward Rotheram, alderman, Robert Bower and Robert Angell, merchants, of London, who were to receive 2,000 chalders of coal and the benefit of two salt pans yearly, Saunders and Paramore guaranteeing the expenditure of £2000 on the works in return for a third share of the Ashburnham, Barkeley and Beaumont interest. No better results followed the efforts of Saunders and Paramore, as, after spending 'great sums' on the salt pans and pits, they were compelled to cease operations and desert the works two years later. Their pits were situated both in Cowpen and Bebside and were connected with the river by means of wooden wagonways, apparently the earliest recorded instance of this means of conveyance, which did not come into general use in the district until considerably later on in the century. [No obvious traces of these pits now remain. But the 19th century OS mapping shows an old coal pit adjoining the river near the railway bridge.]

After Paramore and Saunders retired, their plant, both at Bebside and Cowpen, was appropriated by others. Edward Delaval of Bebside, made free with the rails set upon the land and ground of Bebside for five hundred paces on the wagonway on both sides of the way, while a similar length of way in Cowpen, together with the keels and other utensils and implements, was taken possession of by John White, Alexander Osborne and others, who entered upon the mines as farmers of the Ashburnham and Beaumont interest and occupied them for a further period of three years, when they finally ceased to be worked.

The history of the declining days of the local coal and salt industry at this period has been given in some detail as an instance of the readiness with which capital from London and the south was then generally secured in connection with north-country mines. Mining then no doubt, as it has done ever since, offered the prospect of large returns to the investor, on whom, in his ignorance of the uncertain and risky nature of the business, the much talked of successes of the few made a far deeper impression than the fate of less fortunate speculators.

William Gray, in his Chorographia published in 1649, reflects on the uncertainty of coal mining in the district and sums up his observations with the remark that colliery owning constitutes a great charge, the profit uncertain. Neither did the south-country investor escape his attention, for he continues : "Some south gentlemen hath, upon great hope of benefit, come into this country to hazard their monies in coale-pits. Master Beaumont, a gentleman of great ingenuity and rare parts, adventured into our mines with his twenty thousand pounds; who brought with him many rare engines, not known then in these parts; as the art to bore with iron rods to try the deepness and thickness of the coal; rare engines to draw water out of the pits; waggons with one horse to carry down coals from the pits to the staithes to the river, etc. Within A few years he consumed all his money and rode home upon his light horse."

It is curious that, beyond the reference in the above well-known passage, no mention has hitherto been discovered of the doings of Beaumont in the district. That his appearance must have taken place early in the seventeenth century, or sooner, seems to be proved by the fact that the art of boring was known here as early as 1615. At that date it does not appear to have been very generally practised, mention being made in a letter written in that year by the earl of Northumberland's agent at Tynemouth of the difficulty he experienced in obtaining a borer, the only available one being in the employ of his competitors at Newcastle. The same document contains a note in the earl's handwriting with reference to boring, to the effect that "they try in Sussex for iron-mine much in the same fashion." It is evident therefore that the date at which Huntington Beaumont became one of the lessees at Cowpen corresponds with that of the probable introduction of boring into the north, and his identity with the celebrated individual of the same name seems to be further accentuated by the fact that wooden wagonways (the 'waggons with one horse to carry down coals from the pits to the staithes) were established at Cowpen and Bebside at a date which is evidently much in advance of their general introduction, a mention of wagonways in 1660 having hitherto been considered as the first distinct allusion to their use in the district.

That Huntington Beaumont was identical with Gray's unfortunate Beamont there seems to be no reason to doubt. The tradition that he gave his name to the Beaumont seam may point to the probability of his having had mining interests elsewhere than at Cowpen, which may have accounted for a part of his supposed losses; but, on the other hand.

Gray, writing at a considerably later date, was evidently uncertain of the total, as in his corrected proofs he largely reduced the figure he had originally stated. In any case Beaumont appears to have exercised personal supervision at Cowpen, for he lived at Bebside hall, of which he is described in 1615 as having been lately the tenant with Dorothy Delaval and Edward Delaval. It was probably from that house that he set off on his 'light horse' for his home at Bilborough, a mining village near Nottingham, where he died at the age of 62 in 1623. He was a younger son of Nicholas Beaumont or Beamont, the owner of the Cole-Orton estate in Leicestershire, and, in his day, the largest coalowner in that county, as well as proprietor of an estate at Bedworth in Warwickshire on which coal was also worked. Huntington Beaumont must therefore have been brought up amongst surroundings which influenced his genius for mining. It is thought that, as his 'rare engines' practically all originated from Germany, he may have visited that country in his early days, but of this there is no record to be obtained. ( Beaumont also held a lease of coal in Bedlington in partnership with Sir Percival Willoughby, William Angell, Robert Angell, and Robert Bower. The two last named persons were likewise partners with Beaumont in the Cowpen mines.)

In the survey of the king's coal mines, made in 1621, it is mentioned with regard to Cowpen that there are no coal pits wrought there, but notwithstanding this the Crown continued to let the coal, a lease of the mines, with four salt pans, being taken by David Errington in 1636 for twenty-one years. Errington did not make any use of his lease, and in the particulars taken by order of the Commonwealth commissioners for the sale of Crown lands in 1649, it is stated that the colliery and salt pans had been found to be a mere waste and unoccupied by Errington, who had paid no rent. The property was sold in 1650, though at the Restoration the sale was treated as invalid and the Crown resumed possession. In 1681 a lease was granted to William Urwyn for thirty-one years, a second in 1697 to Edward Hindmarsh of Little Benton for fifteen years, and a third in 1737 to Robert Douglas. A small yearly rent was reserved by these leases with the addition of one-tenth of the profits. No rent, however, was paid and no mining operations were ever undertaken.

The decay of the coal mines in the Blyth neighbourhood seems to have been general during the remainder of the seventeenth century. There is, however, some evidence of shipments having been made during this period, but the trade can only have been a very limited one, although it was of sufficient importance to procure the inclusion of Blyth, along with Newcastle and Sunderland, in an ordinance passed in 1643 prohibiting the export of coal from those ports during the Civil War.

As there is no further trace of coal having been mined at Cowpen until 1710, when Stephen Mitford appears to have been engaged in working on Mr. Sidney's [the main landholder of the western part of Cowpen] estate, it seems probable that the source from which these supplies were obtained were the small collieries which had already been established some five miles or more to the west of Blyth in the neighbourhood of Plessey. These pits lay near to the outcrop of the lower seams, from which coal of a better quality than that hitherto found at Cowpen could be won at little depth, but, through the absence of proper means of transport, could not be carried readily to the seaboard.

Towards the close of the centurv attention seems to have been turned to these inland collieries and to Blyth as an outlet for their produce. From 1688 to 1692 was a highly speculative period in the city of London when, amongst many other joint stock companies, a 'Blyth Coal Company' was formed.

About this date the Plessey and Newsham estates were purchased by Ralph Brandling of Felling and Nathaniel Wyresdale of London, who, there is reason to believe, were acting as agents for a London company interested in securing Blyth as a convenient place for shipping the Plessey coal. Their scheme must, however, have fallen through, as not long afterwards the whole undertaking was made over to Colonel Thomas Radcliffe, who, in 1699, leased Plessey colliery to George Errington of Gray's Inn.

In 1709 Errington secured from Sir John Delaval a right of wayleave through his Horton estate for the purpose of leading coals to the river of Blyth or Blythe's Nook along the well known Plessey Wagonway, which had been constructed before his tenancy commenced, and was the means of establishing Blvth in a firm position as a coal-shipping port. The wagonwav was of the then usual wooden type, and is described in 1716 as extending over a distance of about five and a half miles, terminating in a 'large trunck or gallery to lay coals at the water side and to load ships from,' near which a quay and two salt pans had been established. The life of the wagonway was a long one, for it continued to be used as an outlet for the Plessey collieries until they were finally laid in upwards of 100 years after its formation.

Errington, in 1709, parted with his interest in the undertaking to William Bowman, a London merchant, who, with his partners, carried it on, though with such poor results that, by 1713, the control had virtually passed out of their hands into those of Lord Widdrington, already the owner of collieries at Stella and Winlaton. Operations at this time were on a very modest scale, the three small pits at work affording sufficient coal for the two salt-pans at Blyth and four others on the opposite side of the river, as well as 'ship coals' for the export trade; and, no doubt, the wagonway, with the new quay and 'trunck,' which had been built in 1715, was capable of dealing with larger quantities than the 300 tons of salt and 8,000 tons of coal which constituted the sea-borne trade of that year.

With the attainder of Lord Widdrington and Colonel Radcliffe's heirs in consequence of their share in the rising of 1715, the Plessey and Newsham estates passed to the Crown, and, in 1722, they were purchased by Richard Ridley and Company of Newcastle, who took over the working of the collieries themselves, and appear to have carried on their business with great spirit, the leadings from Plessey to Blyth amounting to about 58,000 tons in 1723.

Collieries had also been established at West Hartford about this date. The coal under this estate was purchased in 1689 by Robert Wright of Sedgefield and John Spearman of Hetton, in the county of Durham,' who in 1719 took a way leave lease over Horton from Admiral George Delaval, in which it was stipulated that they should set apart and dowel out some convenient place on the south side of the river Blyth within the liberties of Newsham, wherein they have an estate for building staiths and wharves for the said West Hartford collieries, to be used by Admiral Delaval for the purpose of building a wharf.

Although no trace of Wright and Spearman's wagonway remains, there seems to be no reason to doubt that one was constructed and used by them for shipping coal from West Hartford, part of their plant having been bought by the Ridleys, who by 1728 had absorbed the West Hartford undertaking.

In 1730 Richard and Nicholas Ridley were carrying on an extensive business at Blyth as general merchants and colliery owners. They held command of the whole of the trade from the Plessey and Hartford collieries and had already extended the quay between the keel and boat docks, which had been built in 1715.

In 1734 the quantity of coal brought to Blyth from Plessey fell little short of 80,000 tons; of this about 2,700 tons were sent 'overseas,' the remainder being shipped coastwise, with the exception of that utilized in the manufacture of salt. The Ridleys had at this time fourteen salt pans at work, six of which had been transferred from Cullercoats in 1726, and their annual output of salt had reached 1,000 tons.'

Towards the close of the seventeenth century Bebside had again become a field for mining speculators, for in 1692 Thomas Ogle of Bedlington leased his land and collieries there to Sir Richard Neile of Plessey and John Pye of London, who covenanted not to cease working them for more than six months, 'unless hindered for want of wind to their mills and engines, or superfluity of water and styth, or a general obstruction of the coal trade.' The position of these pits is doubtful, but probably they were not far from the river, which was used by the lessees as a means of conveying the produce of the upper and poorer seams to Blyth. In 1702, Ogle sold Bebside to John Johnson, a Newcastle hostman, who presumably continued to work the mines, as, by his will made in 1727, he left his colliery at Bebside to his son-in-law, Matthew White of Blagdon, and his daughter, Mary Johnson, as tenants in common. Although mention is made of these mines at later dates, nothing is known of their subsequent working, and it may be surmised that, through lack of adequate means of transport and proper shipping facilities, they failed to make headway and so were discontinued.

Comments

Thanks Peter. We have a rough idea where the pits and wagonways are especially the later ones where some maps are available. Unfortunately the land has been built over destroying any evidence that could be obtained from aerial archaeology, as is available in the 18th century coalfield behind Seaton Delaval Hall, so it would be difficult building a retrospective map. Appreciate the comment though.

An excellent read Alan, answered many questions I had from a thread on Facebook. It would be an interesting and fascinating project to try and plot the pits, saltpans and waggonways onto the modern landscape. Has anyone tried?Thanks again, much appreciated, cheers Pete